A centrifugal air compressor serves as a vital component in various industrial applications, known for its high efficiency and reliability. To promote smooth operation and enhance the lifespan of these compressors, regular daily maintenance is crucial. This article will provide an in-depth overview of effective daily and routine maintenance practices for centrifugal air compressors.

Daily Maintenance

Start with checking and replacing the filter: The filter is essential for removing impurities and oil from the air within the centrifugal air compressor. Regularly inspect the filter, and if it appears blocked or compromised, replacing it promptly will help maintain optimal performance.

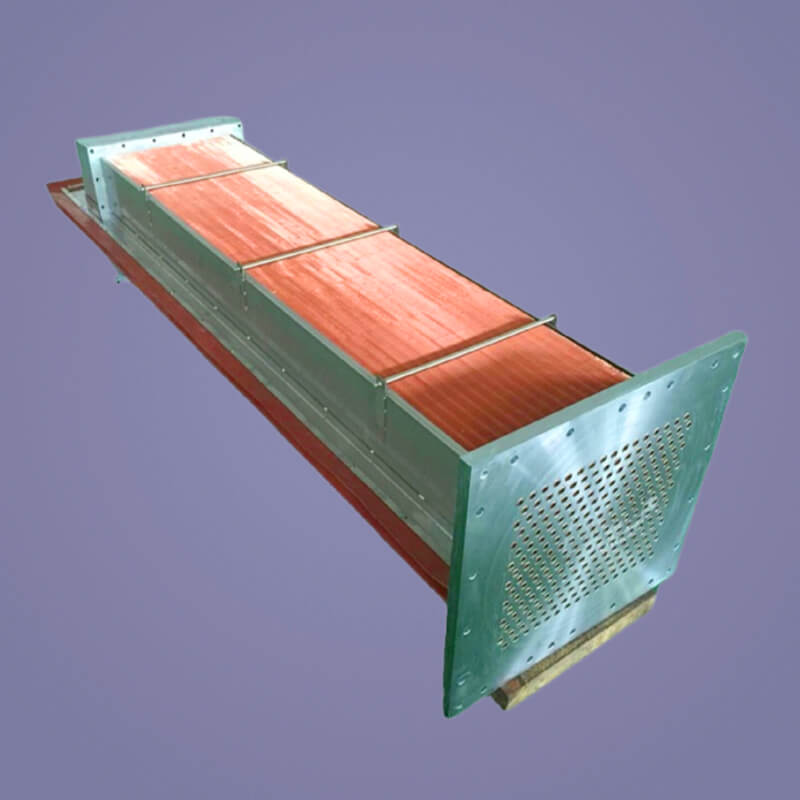

Next, clean the cooler: Positioned at the air outlet, the cooler is responsible for cooling the air. Ensure that dust and dirt are removed from the surface of the cooler regularly to support efficient heat dissipation.

Additionally, assess the lubricating oil: Monitoring the quality and quantity of the lubricating oil is vital. Regular checks will ensure the filling port remains clean, and that the lubricating oil meets necessary quality standards.

Lastly, inspect the electrical system: A routine check of the electrical components is important. Verify that connections are secure, there is no evidence of overheating, fuses are intact, and that the electrical circuit shows no signs of damage.

Regular Maintenance

Plan for the replacement of wearing parts: Following the manufacturer's guidelines, it's important to schedule the replacement of components such as bearings, gears, and seals based on the compressor's operational usage.

Evaluate the screw rotor: Regular inspections for wear or cracks in the screw rotor are essential to prevent larger issues. Address any abnormalities immediately.

Examine the cylinder: Checking for scratches or wear on the cylinder's inner wall and inspecting the seals for aging or damage is critical. Timely intervention can prevent bigger problems down the line.

Ensure pressure gauge calibration: Regularly calibrating the pressure gauge will help maintain accurate pressure readings, which is key for overall system efficiency.

Precautions

Always consider avoiding prolonged overload operation to protect the service life of the centrifugal air compressor.

Vigilantly monitor sounds and vibrations during operation. If any irregularities arise, stopping the compressor for timely inspection is advisable.

Operators should be well-acquainted with the compressor's operating procedures and adhere to safety protocols, ensuring safe and efficient operation.

By implementing these daily and routine maintenance practices, we can greatly enhance the performance and longevity of centrifugal air compressors, ultimately leading to a more reliable and efficient industrial operation.